Withering process is the foundation for achieving quality in tea manufacture

PRESENT PRACTICE for withering

In the present working at tea factories, all the withering processes  are being done manually and all the parameters are also being monitored and supervised manually. Because of present manual processing and manual monitoring, consistency in withering is not being achieved adversely affecting the quality of final tea made.

are being done manually and all the parameters are also being monitored and supervised manually. Because of present manual processing and manual monitoring, consistency in withering is not being achieved adversely affecting the quality of final tea made.

TO OVERCOME these deficiencies in withering process, Stesalit has developed a highly user-friendly and version of Intelligent Tea Withering Monitoring and Control System (TWMAC) which gives uniform and consistence withered tea enhancing the quality of final tea produced.

System Overview

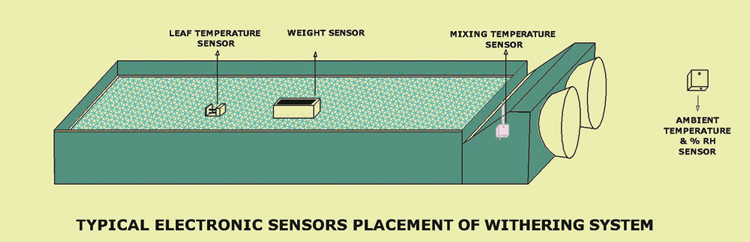

This system monitors the withering process intelligently by following the calculated weight loss profile of leaves with respect to elapsed time against a pre-set profile. For this, a sample weight of leaf is kept in a specially designed box at the same density as spread in the whole trough bed. Weights are automatically monitored in every 30 minutes of withering operation by switching OFF the fan automatically for about 4 minutes. The fan operation is controlled based on the weight loss trend at each weight monitoring interval. If the rate of weight loss (moisture removal) is lower with respect to desired weight loss, then fan will automatically switch ON and run continuously till the next weighing interval, simultaneously alarm with visual LED indication of WET condition displayed for manual hot air introduction if required. If weight loss is higher, then fan would remain switched OFF till next weighing interval with visual LED indication of DRY condition. After achieving the desired set % wither, fan will be automatically switched OFF and it will alert the user through audio visual annunciation about the completion of process. Hot air application is decided based on ambient RH and weight loss trend through audio visual annunciation.

Through this, Intelligent Tea Withering Monitoring and Control System, a uniform quality of withering in tea is achieved, resulting in higher price for the final tea made. This system also saves considerable energy by monitoring the weight loss trend with respect to time and keeping the fan off when not required. The payback period for this system, in terms of energy saving alone (without considering the better realization for better quality of tea made) is less than 10 months.

Salient Features / Advantage

- Consistency in withering of tea leaves every time

- System is suitable for both CTC and Orthodox Tea processing

- User Settable withering time and % withering

- On line display of % withering and remaining time for wither complete

- Significant energy saving by monitoring the weight loss trend with respect to time and keeping the fan off

- Enhance the withering quality, results in to produce quality tea for better price realisation of tea made

- Computer interface for remote monitoring of entire process parameter (optional)

- Audio Visual annunciation to guide the operator for applying the hot air based on change in ambient condition